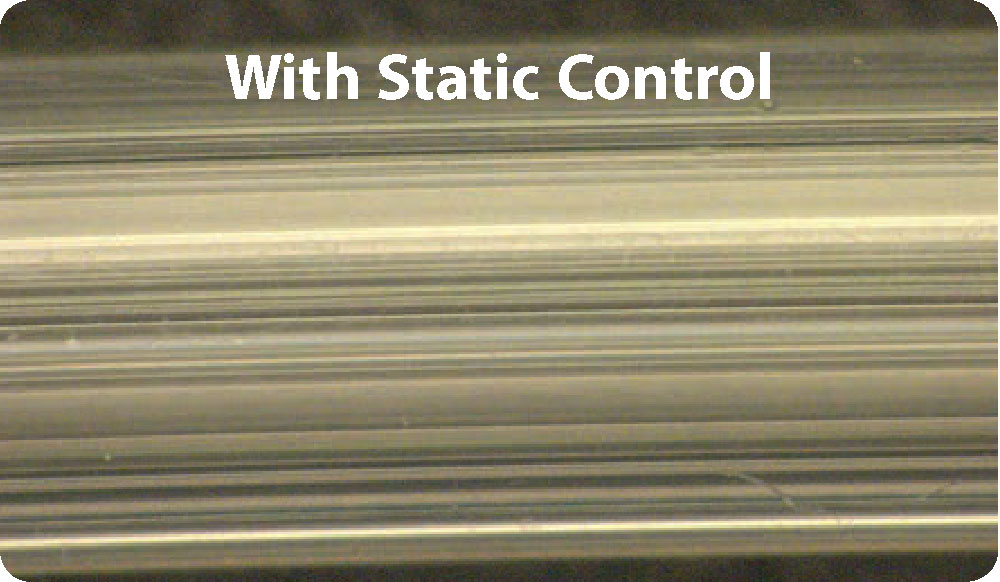

Managing static electricity is important for several

reasons. The most notable being contamination control, operator safety, and minimizing process equipment issues that can occur due to high static charges. Contamination control is a significant issue in many manufacturing environments, especially in critical applications such as food, medical or pharmaceutical packaging.

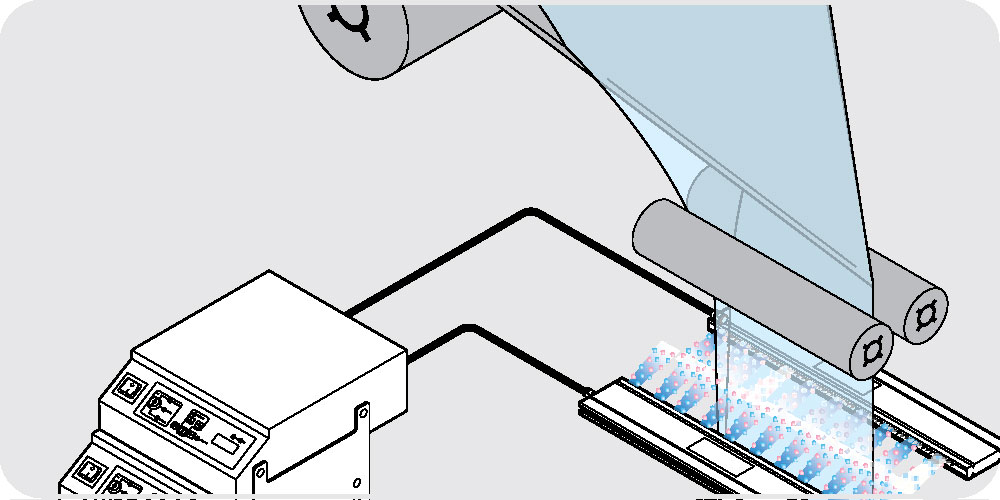

Operator safety is also a critical concern because high static charges can cause significant electrostatic shocks to unsuspecting personnel, or worse, an electrostatic discharge in a solvent coating application could cause a fire hazard. The biggest issue for most manufacturers is that all of these problems resulting from static electricity impact their bottom-line.